Products

Contact Us

Dark tea

Product ID:D091

PVB interlayer film is a translucent film made from polyvinyl butyral resin that is plasticized and extruded with a plasticizer. It is primarily used in laminated glass, which is a special type of glass formed by sandwiching a layer of PVB film between two pieces of glass and then subjected to high pressure and heat.

Product Details

Product Features

PVB interlayer film is a translucent film made from polyvinyl butyral resin that is plasticized and extruded. It is mainly used in laminated glass, which is a special type of glass formed by sandwiching a layer of PVB film between two pieces of glass and then applying high pressure and heat. PVB laminated glass has multiple functions such as safety, thermal insulation, noise control, and UV isolation.

The appearance of PVB interlayer film is a translucent film, free of impurities, with a smooth surface, certain roughness, and good flexibility. It has excellent adhesion to inorganic glass and possesses characteristics such as transparency, heat resistance, cold resistance, moisture resistance, and high mechanical strength, making it widely used in architectural laminated glass and automotive safety glass.

Main Performance of PVB Film

Starting from the basic properties of ordinary interlayer films such as safety, anti-theft, and UV filtering, high-performance interlayer films with added privacy and thermal insulation, as well as highly creative PVB films for decoration and visual control, have been fully showcased in the trend of modern architectural glass.

Product Features

PVB interlayer film has a very strong adhesive force. Laminated glass using PVB interlayer film can absorb impact forces. When the glass shatters, the glass fragments will firmly adhere to the PVB interlayer film, keeping the entire glass structure intact. Even a glass cutter cannot penetrate it, providing anti-theft protection and preventing injury to others from falling shards, especially suitable for high-rise building glass, including sunrooms, canopies, railings, and walkways.

Nano Insulation Film Product Features

Nano insulation PVB interlayer film ~ light blue, can effectively block over 90% of UV and infrared rays, while also effectively blocking the conduction of heat between indoors and outdoors, thus achieving energy-saving effects.

| Summary of Data for Nano Insulation Interlayer Glass | |||||

| Serial Number | Interlayer Film Name | Glass Configuration | UV Blocking Rate % | Infrared Blocking Rate % | Visible Light Transmittance % |

| 1 | Type 90 Insulation | 5+0.38 Insulation+5 | 99.3 | 91.2 | 74.1 |

| 2 | Type 95 Insulation | 5+0.38 Insulation+5 | 98.3 | 95.1 | 67.4 |

| 3 | Ford Blue Insulation | 5+0.38 Insulation+5 | 97.4 | 92.1 | 33.9 |

| 4 | EVA Insulation | 5+0.76 Insulation+5 | 98.0 | 85.0 | 75.0 |

| 5 | Type 98 Insulation | 5+0.76 Insulation+5 | 99.2 | 98.2 | 65.2 |

| Long-term Observation Data Table for Nano Insulation Interlayer Film | ||||

| Time | Project | Visible Light Transmittance (%) | Infrared Blocking Rate (%) | UV Blocking Rate (%) |

| 180826 | Not Exposed | 68.2 | 91.1 | 99.2 |

| Covered for 3 Days | 67.8 | 91.3 | 99.1 | |

| Exposed for 1 Month | 67.5 | 91.2 | 99.1 | |

| Exposed for 2 Months | 67.6 | 91.2 | 99.1 | |

| Exposed for 3 Months | 67.9 | 91.4 | 99.1 | |

| 190826 | Exposed for 1 Year | 67.9 | 91.4 | 99.1 |

| 200826 | Exposed for 2 Years | 67.9 | 91.6 | 99.1 |

| 210826 | Exposed for 3 Years | 67.7 | 91.3 | 99.1 |

| 220826 | Exposed for 4 Years | 67.8 | 91.4 | 99.1 |

Product Details

Transparent/matte film/jade sand film/insulation film/matte insulation film/black/ceramic white film/energy-storing luminescent film and various functional colored PVB interlayer films, professionally customized, providing you with different choices.

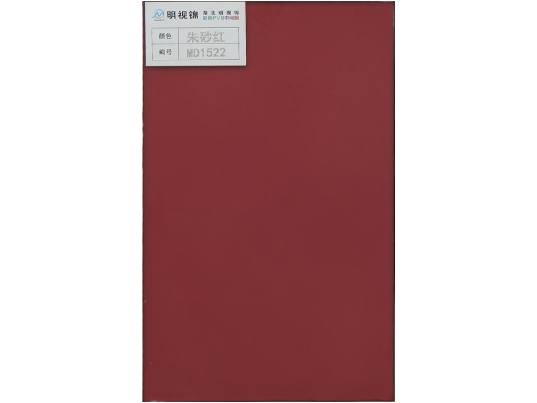

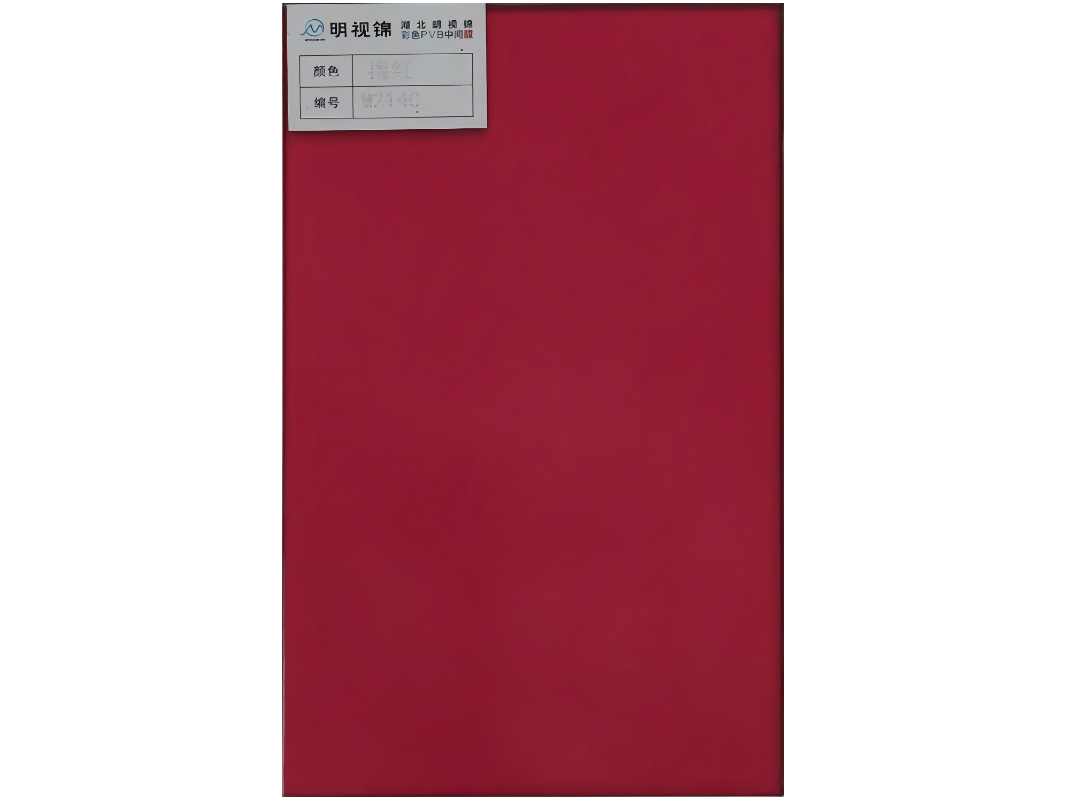

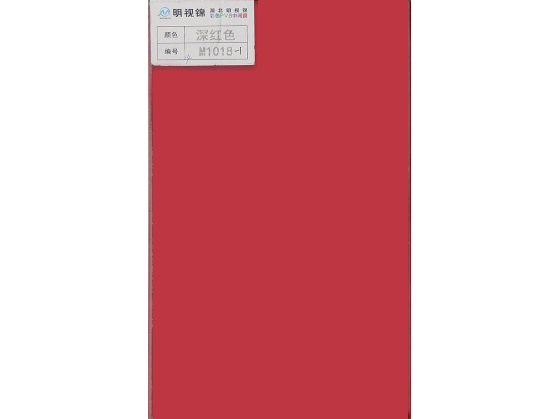

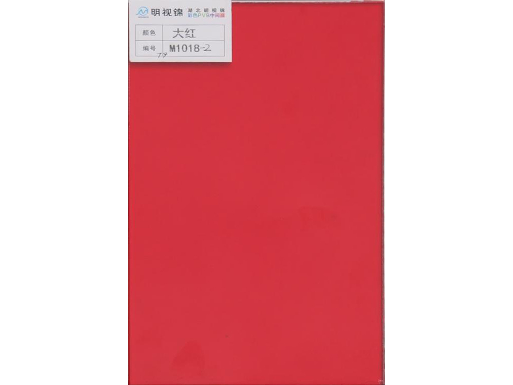

Color

High light transmittance, low haze, and high color consistency.

Specifications

Thickness Customization: 0.38-1.52mm

Width Customization: 500-3500mm

Color Customization: Various colored PVB interlayer films available from 0.30-1.52

Product Packaging

Outer Packaging: Color customization available for various colored PVB interlayer films from 0.30-1.52

Inner Packaging: Paper core, isolation film, vacuum-packed aluminum foil bag, qualitative foam tray, labeled with certification.

Technical Parameters

| Project/Category | 0.38mm | 0.76mm |

| 1. Appearance Requirements | ||

| 1.1 Appearance | Colorless or slightly yellow transparent film, smooth surface, no scratches or creases. | |

| 1.2 Spot Impurities and Bubbles | ||

| ≤0.05mm² >0.05 mm² |

Allowed to exist dispersed. No more than 10 occurrences per roll. | |

| No more than 8 occurrences per roll. | No more than 5 occurrences per roll. | |

| Marking required. Each definition extends 0.5 linear meters. Add 1 meter for each occurrence. | ||

| 2. Geometric Dimensions | ||

| 2.1 Thickness | 0.38+0.02 | 0.76±0.02 |

| 2.2 Uniformity | Lateral thickness deviation within 25mm distance not exceeding 15. Lateral thickness deviation within 50mm distance not exceeding 20. |

|

| 2.3 Length Tolerance (m) | 0-5 | 0-2 |

| 2.4 Width Tolerance (mm) | 0-20 | |

| 3. Moisture Content | 0.4-0.6 | |

| 4. Tensile Strength (Mpa) | ≥20.0 | |

| 5. Elongation at Break (%) | >200 | |

| 6. Haze (%) | <0.4 | |

| 7. Shrinkage Rate (60℃/15min) (%) | G13 | |

Tags: Dark tea

Product inquiry

If you are interested in our products, please fill in the form below and we will contact you as soon as possible.

Contact Information

Address: No.4 Wanhua Avenue, Ziling Town, Dongbao District, Jingmen City

Official website:http://www.msjpvb.com/

Mobile Access

Powered by www.300.cn This website supports IPV6 access